Technology

Research and analysis

Expanding the potential of high-damping rubber

With the aim of further advancing high-damping rubber and vibration control technologies and promoting their widespread adoption, we conduct joint research with university research institutions to realize practical applications in various fields.

Our building dampers have obtained official certification.

Sumitomo Rubber's high-damping building dampers have been certified by the General Building Research Corporation of Japan (GBRC) with a Certificate of Architectural Performance.

GBRC Performance Certificate No. 11-30 (March 2012)

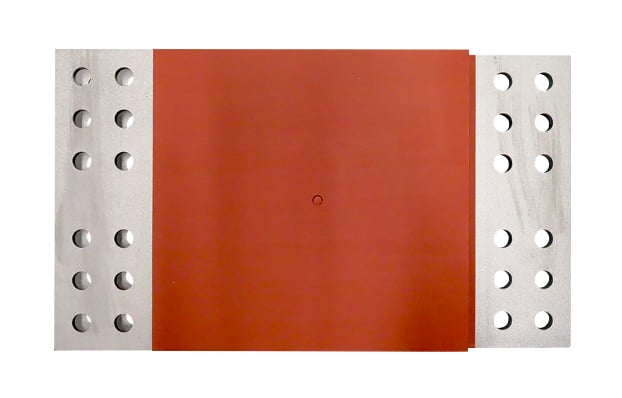

“Viscoelastic Dampers Using Isoprene Rubber-Based Viscoelastic Materials” (SR4015-GR4 / SR4020-GR4)

Analytical models and case studies

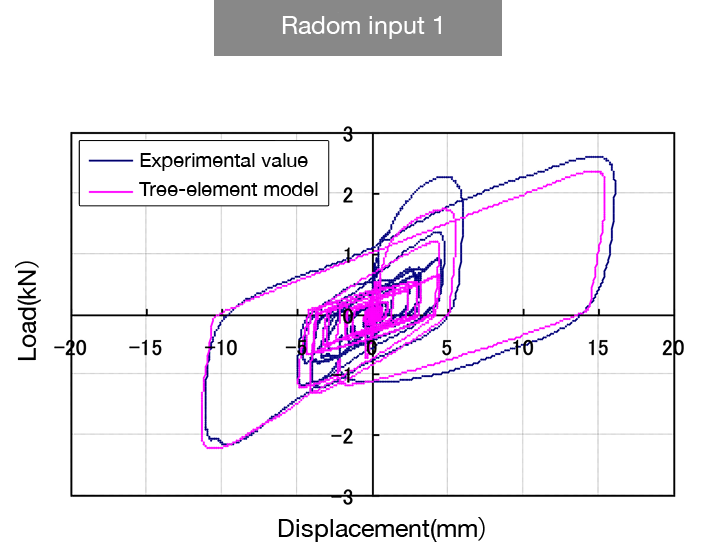

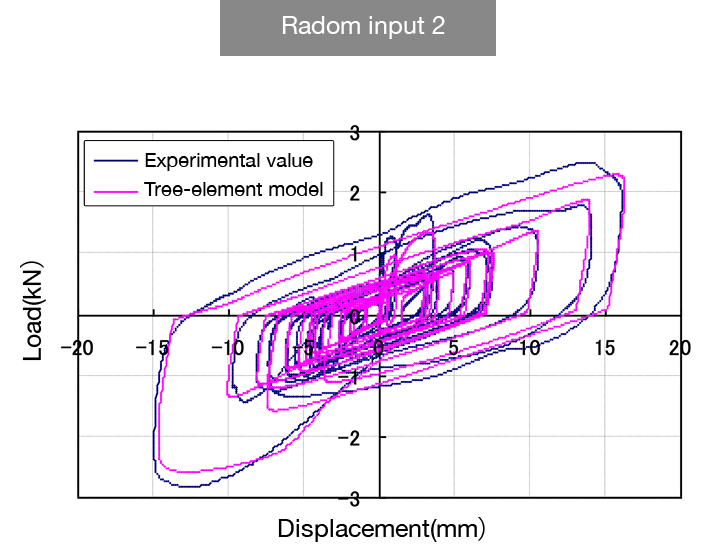

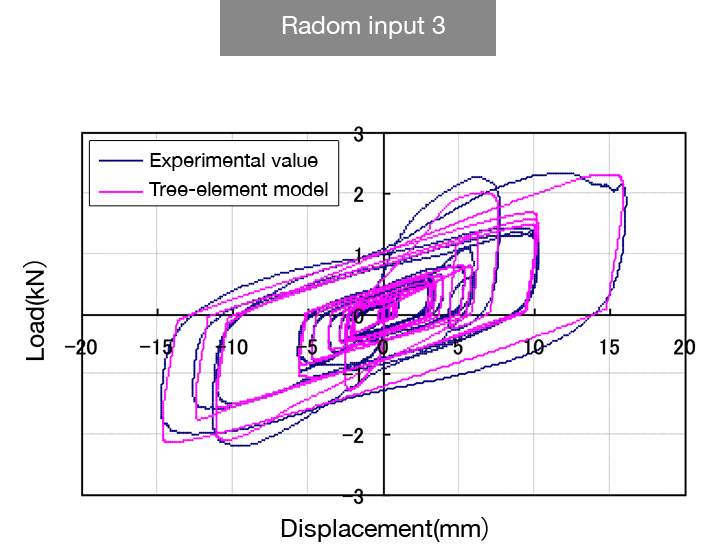

We have developed a high-precision analytical model that accurately captures the characteristics of high-damping rubber, and it has been incorporated into a general-purpose dynamic analysis program.

*Excerpted from the performance certificate obtained in 2012 from the General Building Research Corporation of Japan (GBRC).

| Maximum load (kN) | Cumulative energy (kN·mm) | |||||

|---|---|---|---|---|---|---|

| Test① | Model② | ①/② | Test① | Model② | ①/② | |

| JMA Kobe | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 |

| Taft | 2.33 | 2.33 | 2.33 | 2.33 | 2.33 | 2.33 |

| El Centro | 2.33 | 2.33 | 2.33 | 2.33 | 2.33 | 2.33 |

List of Supported Software

SNAP (KOZO SYSTEM Inc.), SS21/dynamic PRO, 3D dynamic (Union System Inc.), MIDAS (MIDAS IT)

RESP-D/F3T (KOZO KEIKAKU ENGINEERING Inc.), ETABS, SAP2000 (Computers and Structures, Inc.)

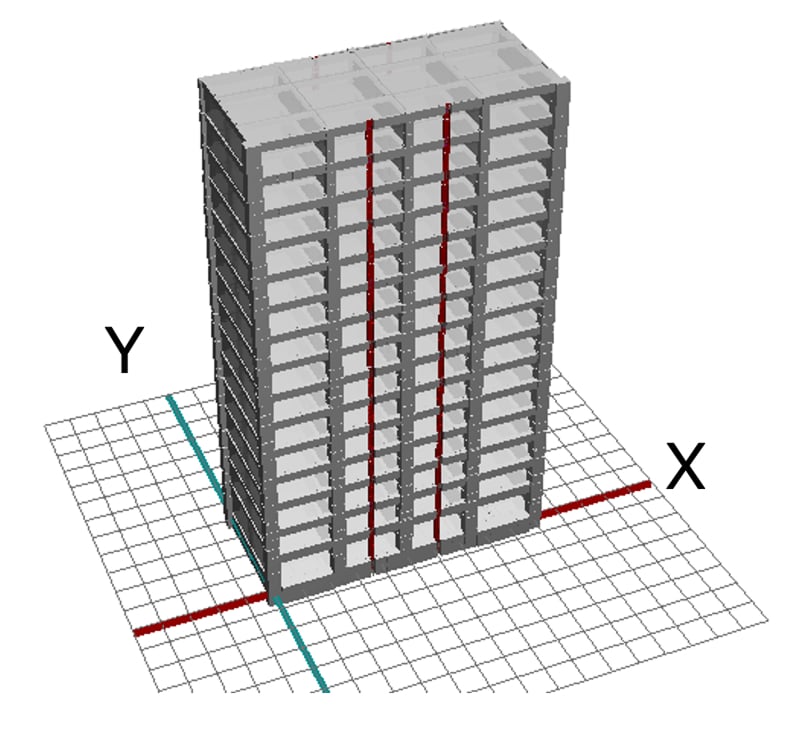

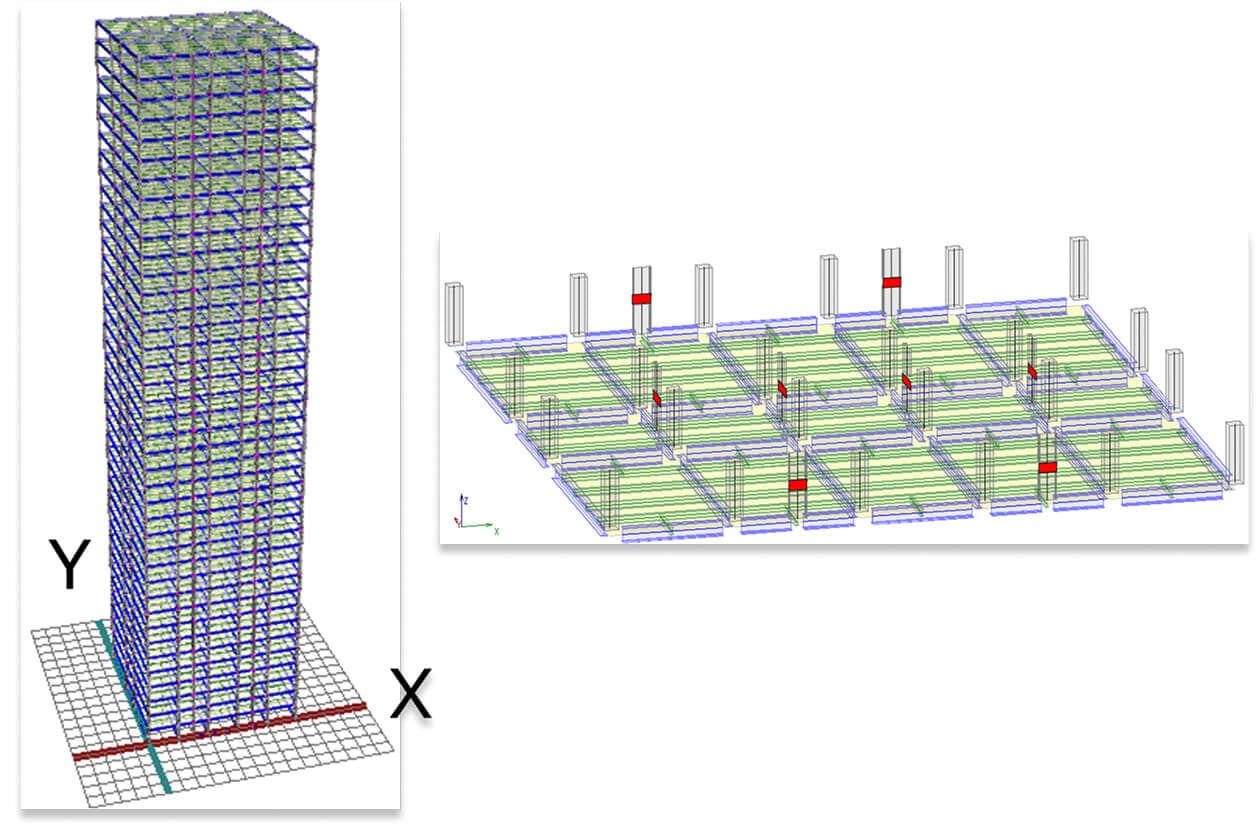

Reinforced Concrete (RC) building with 15 stories (26m x 15m x 45m)

Principal direction: X

Fundamental natural period: 0.86 s

Input: BCJ-L2

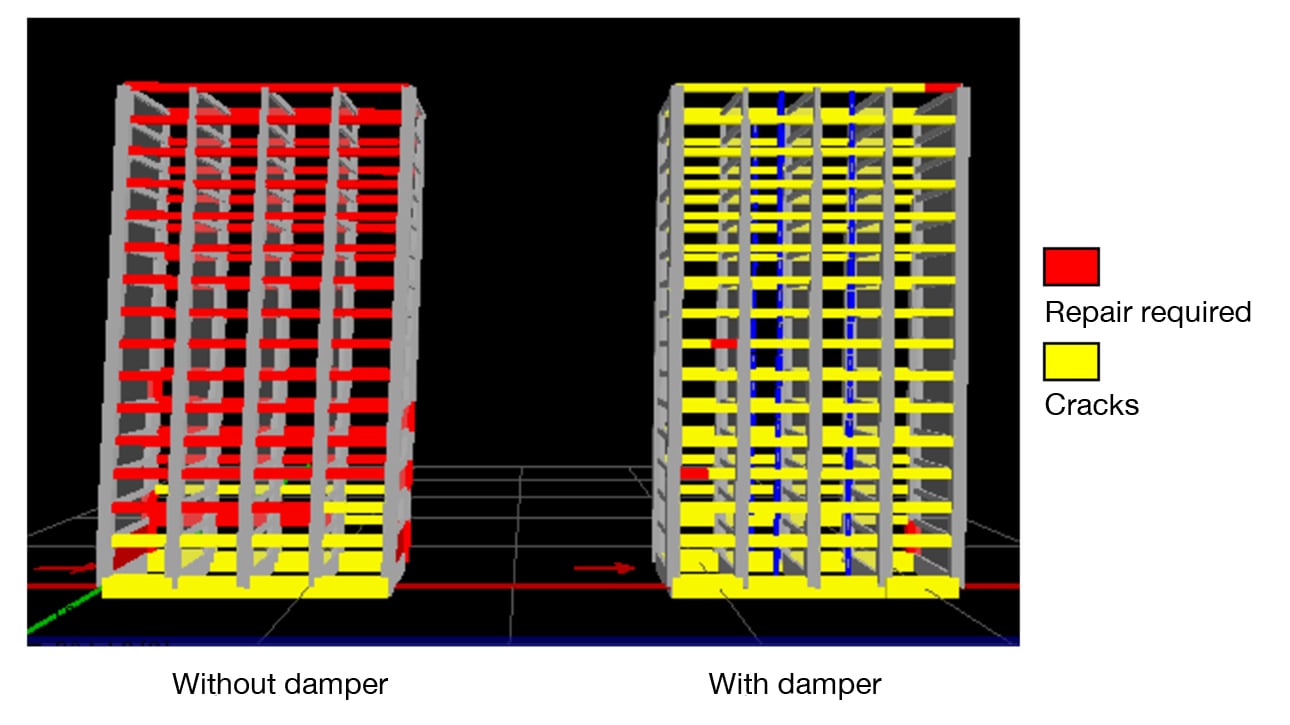

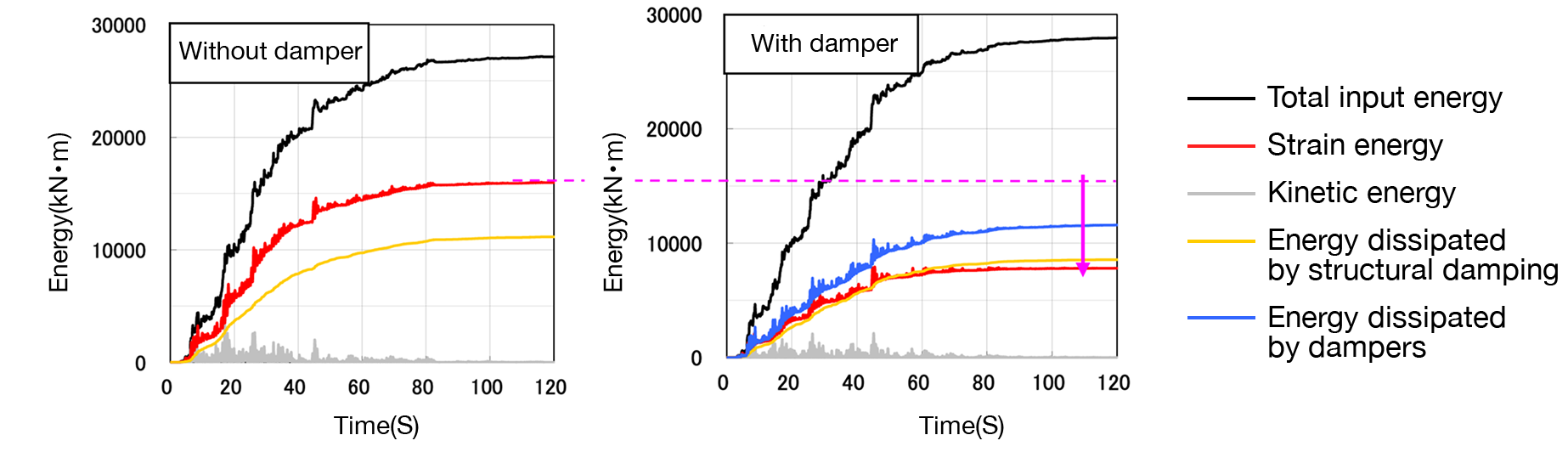

By having the damper dissipate the energy of the vibration input to the building, the building’s strain energy (= damage) is significantly reduced.

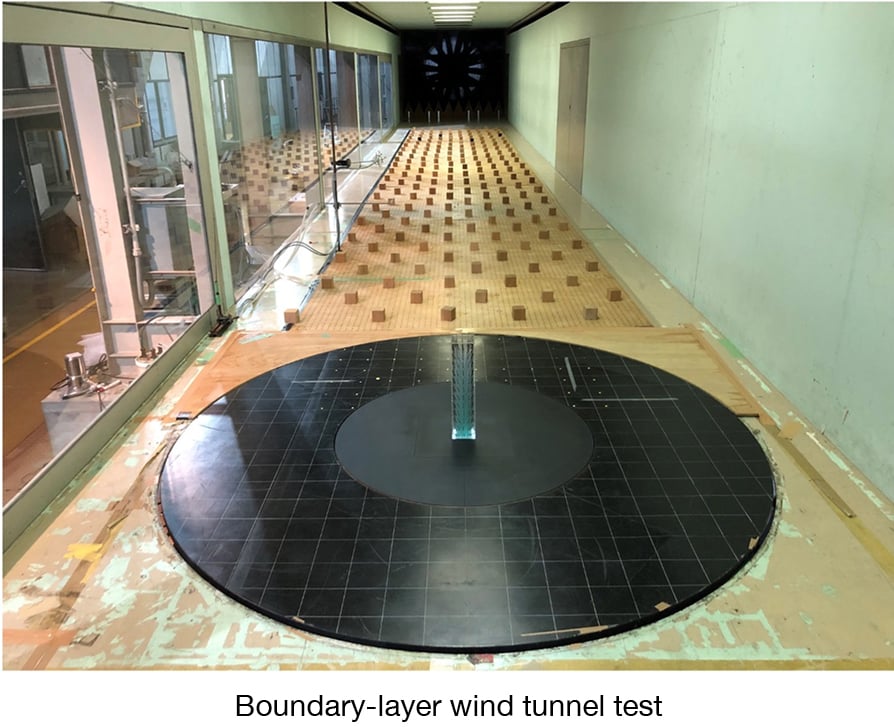

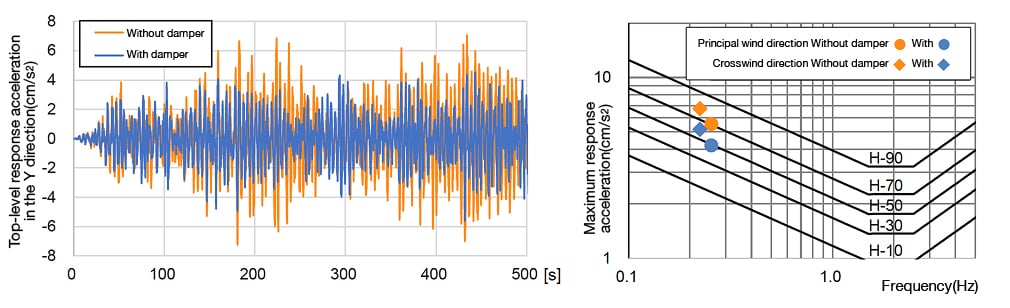

Wind tunnel experiments were conducted to verify the effectiveness against wind-induced vibrations.

Steel Reinforced Concrete (SRC) building with 40 stories (36m×36m×160m)

Principal wind direction: X

Design wind speed: 19m/s

Ground surface roughness category: III

*Results based on analyses performed by Sumitomo Rubber Industries using the structural analysis software SNAP (KOZO SYSTEM Inc.).

Effective even for minor vibrations at the level of residential comfort evaluation.

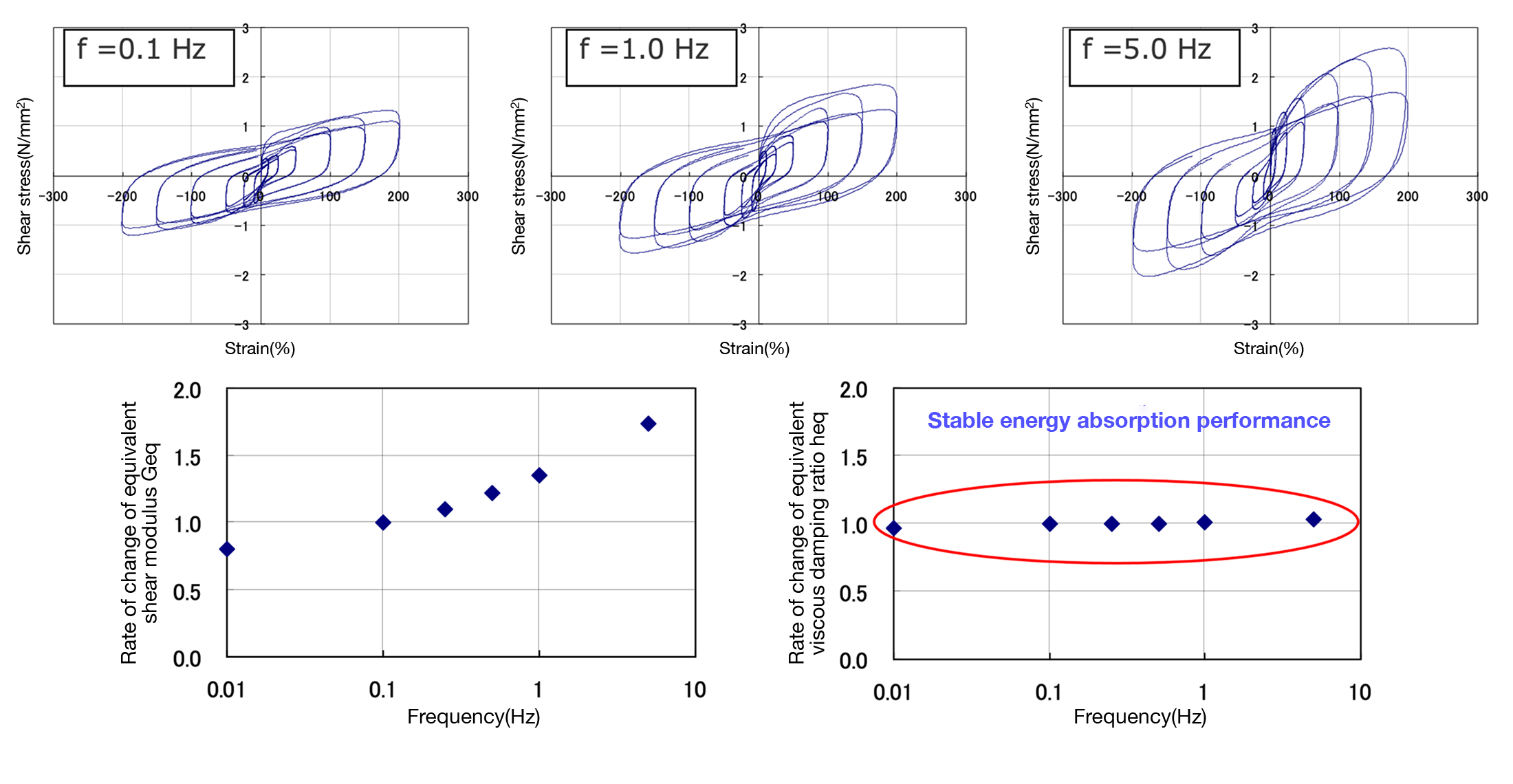

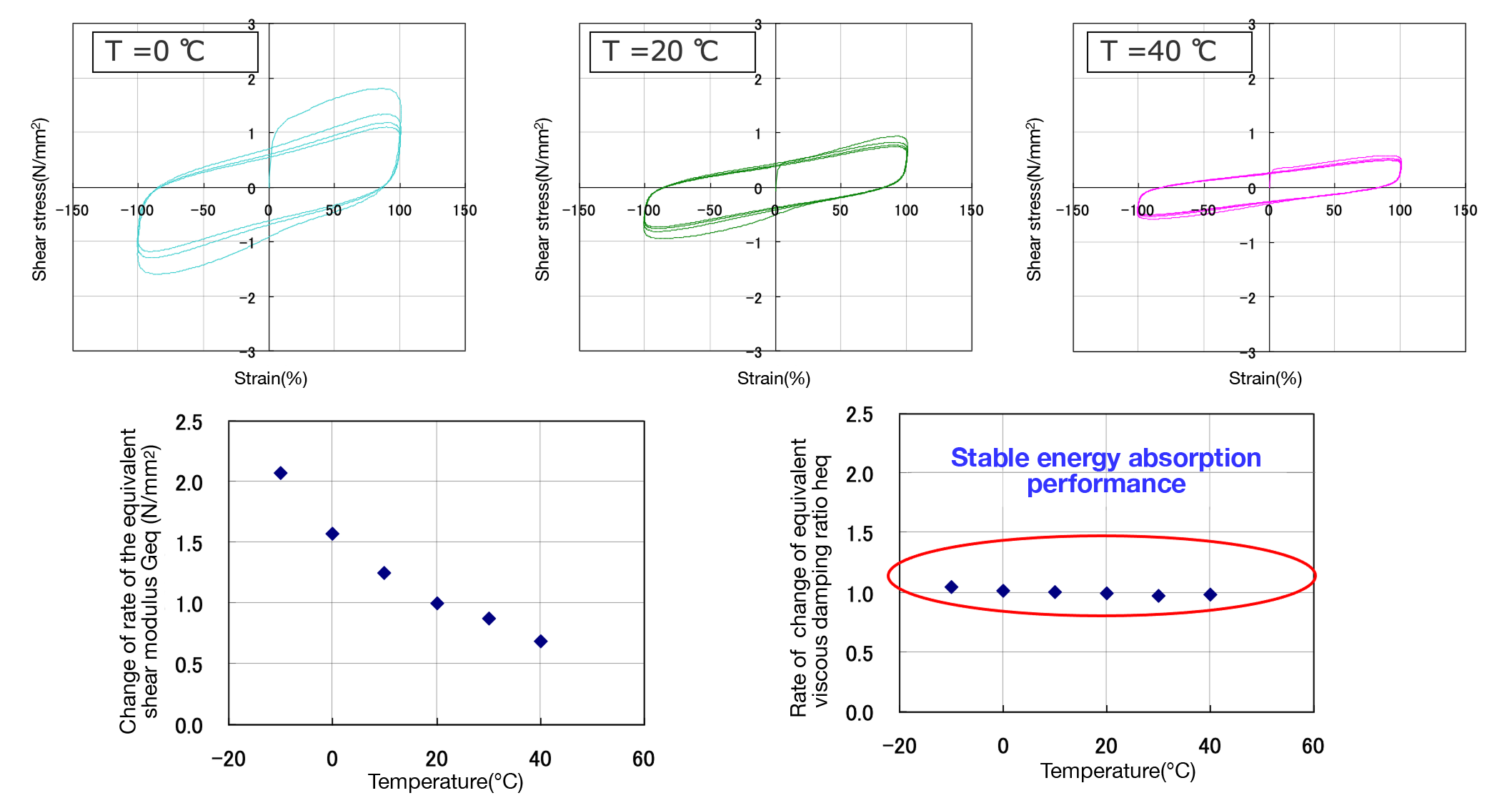

GBRC Performance certificate No. 11-30

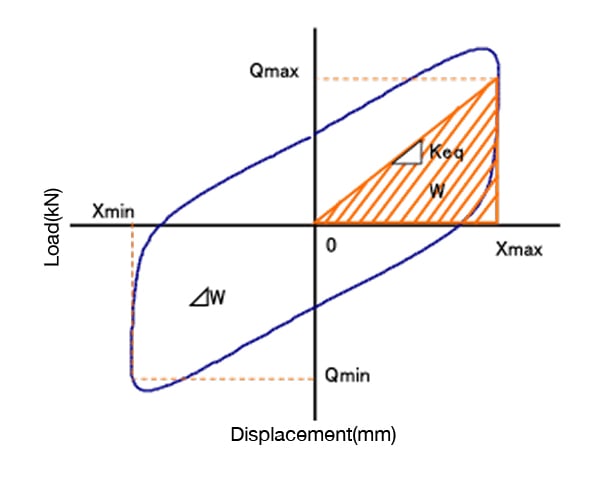

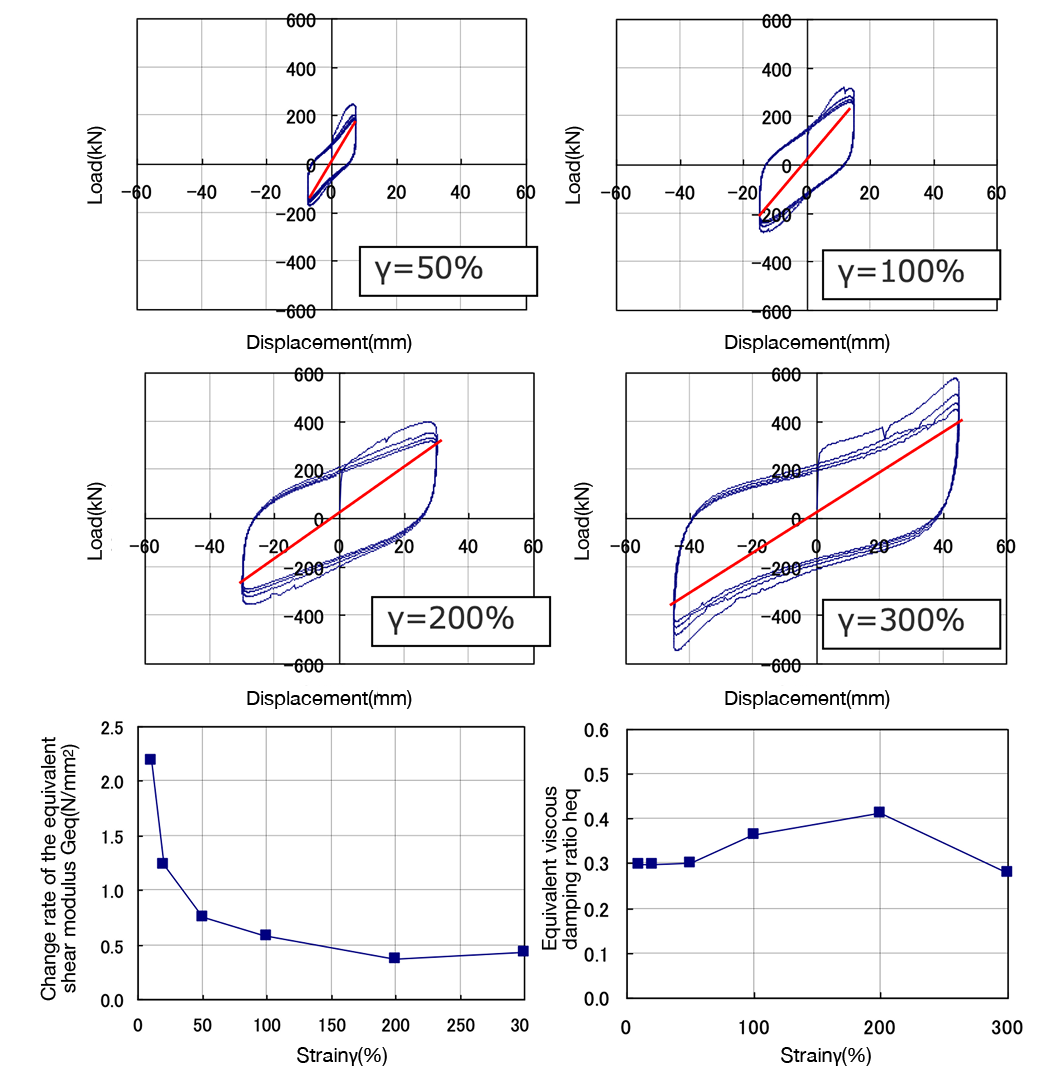

(1)Equivalent stiffness Keq(kN/mm)

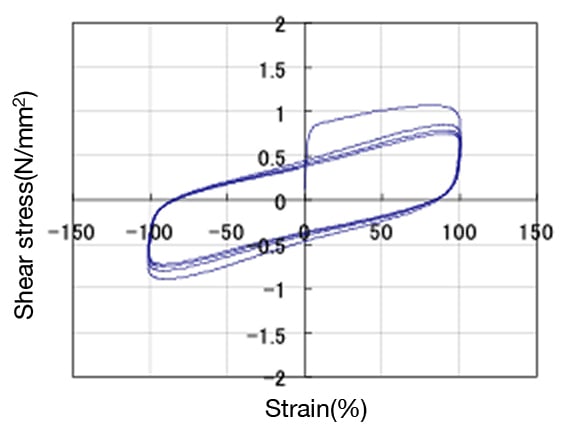

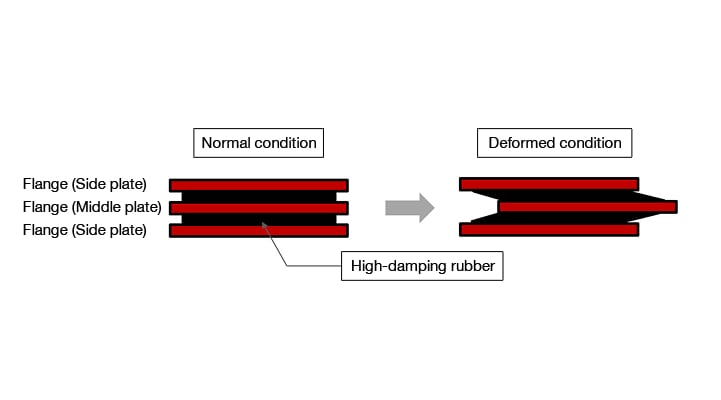

The equivalent linear stiffness refers to the stiffness obtained when the nonlinear restoring force characteristics of the viscoelastic material (high-damping rubber) are replaced by an equivalent linear restoring force. It is calculated based on the following formula.

\( \text{Equivalent stiffness} \)

\( \mathrel{K_{eq} = \dfrac{Q_{max}-Q_{min}}{X_{max}-X_{min}}} \) (kN/mm)

\( Xmax \) :Maximum displacement of the hysteresis loop (mm)

\( Xmin \) :Minimum displacement of the hysteresis loop (mm)

\( Qmax \) :Load at maximum displacement of the hysteresis loop (kN)

\( Qmin \) :Load at minimum displacement of the hysteresis loop (kN)

(2)Equivalent viscous damping ratio heq

The equivalent viscous damping ratio is a measure representing the damping effect determined by the equivalent stiffness and the absorbed energy. It is expressed by the following formula as the ratio of the area of absorbed energy to the strain energy.

\( \text{Equivalent viscous damping ratio}\)

\( \mathrel{h_{eq}=\dfrac{1}{4\pi }\cdot \dfrac{\Delta W}{W}} \)

\(ΔW\) :Absorbed energy (kN・mm), the area within the hysteresis loop

\(W\) :Strain energy (kN・mm), calculated as the area of a triangle determined by the equivalent stiffness and the average of the maximum and minimum displacements.

\( W = \dfrac{K_{eq}}{2} \cdot ( \dfrac{X_{max}-X_{min}}{2} )^{2} \)

(3)Equivalent shear modulus Geq(N/mm2)

The equivalent shear modulus is a coefficient that represents the material properties of the viscoelastic material (high-damping rubber) regardless of its shape, and is defined as the equivalent stiffness Keq divided by the ratio of shear area S to thickness t.

\( \text{Equivalent shear modulus} \)

\( \mathrel{G_{eq} = \dfrac{K_{eq}}{(S/t)} \cdot 1000} \) (N/mm2)

\(t\) :Viscoelastic layer thickness (mm) \(S\) :Shear area of the viscoelastic material (mm2) *Excerpted from the performance certificate

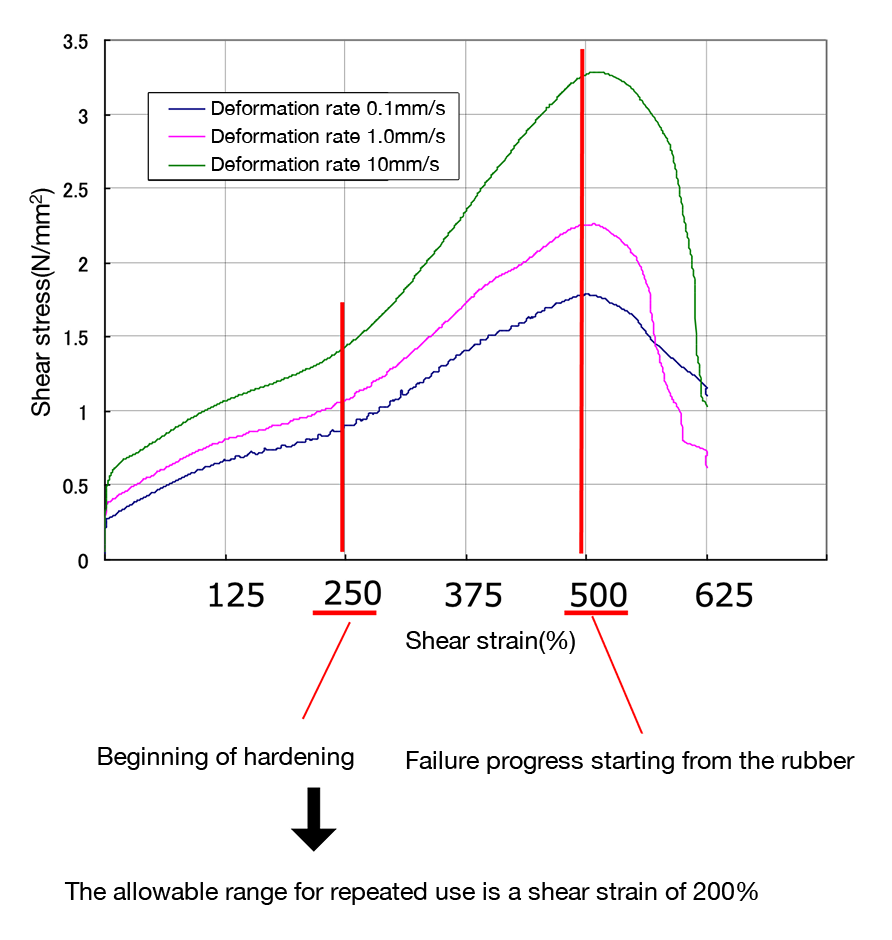

Supplementary test report

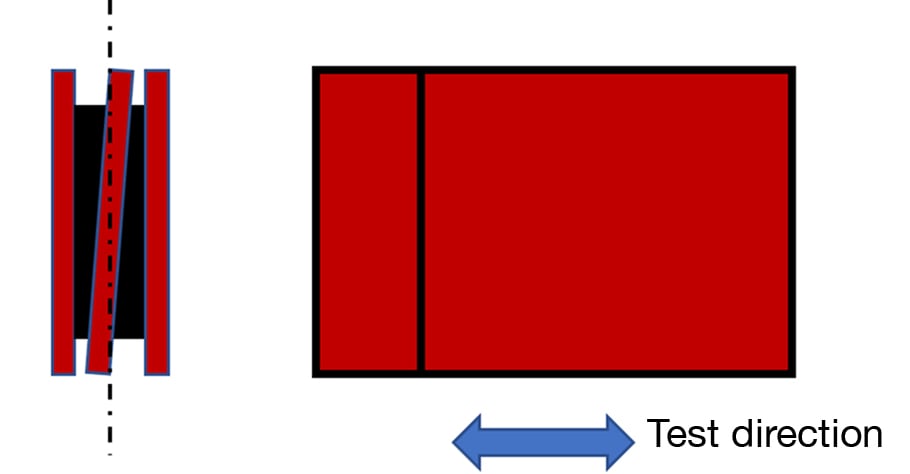

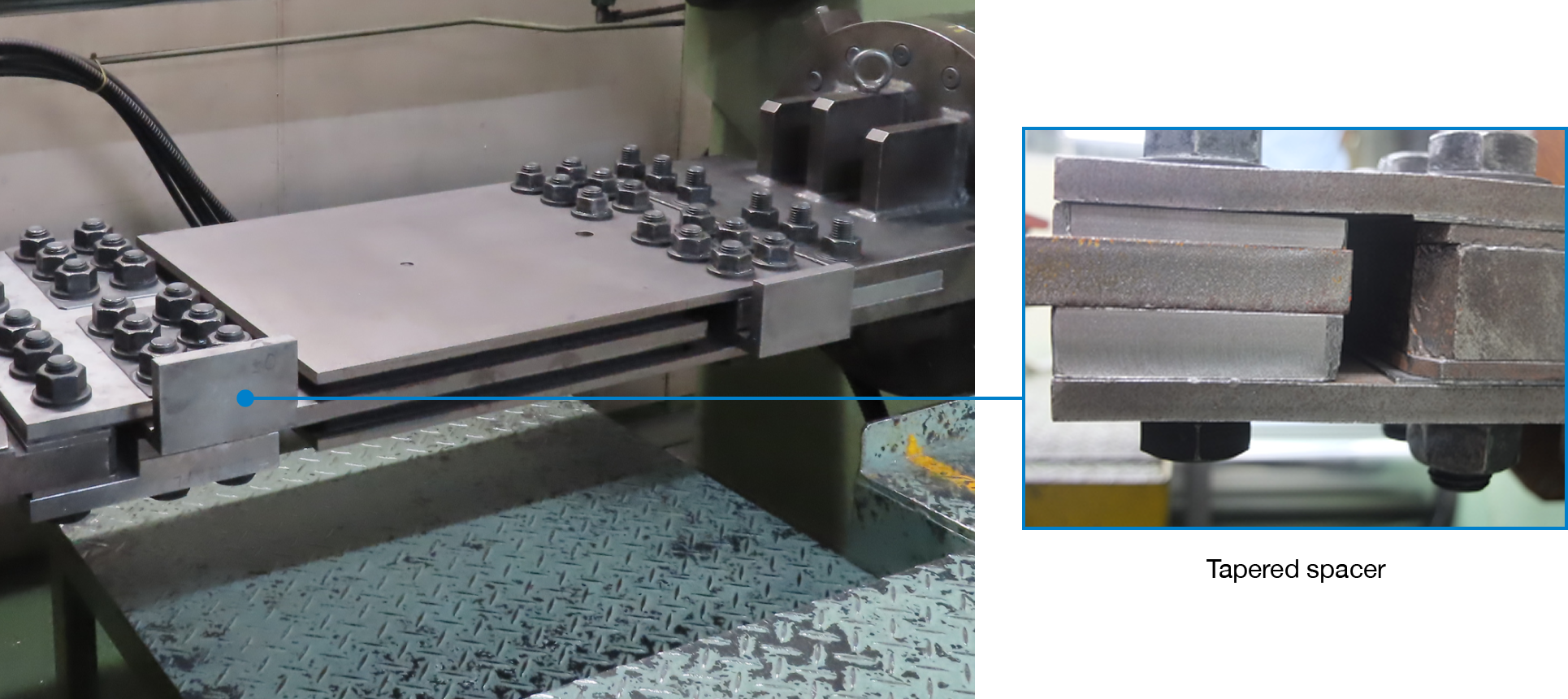

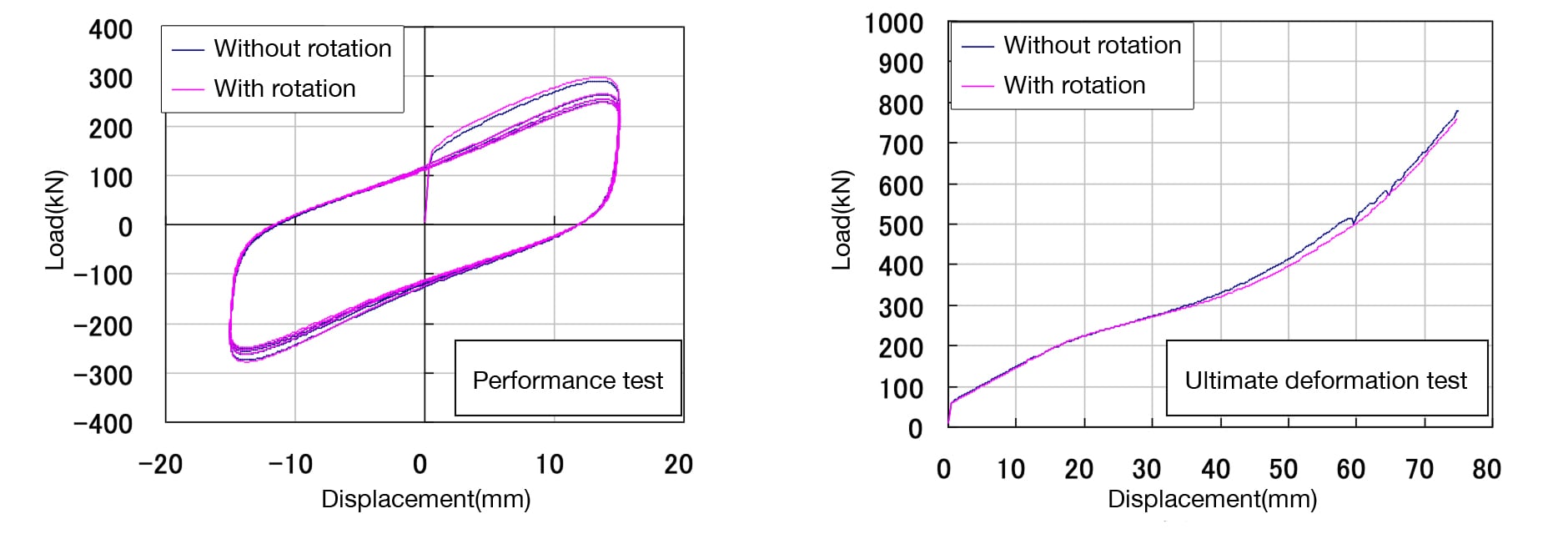

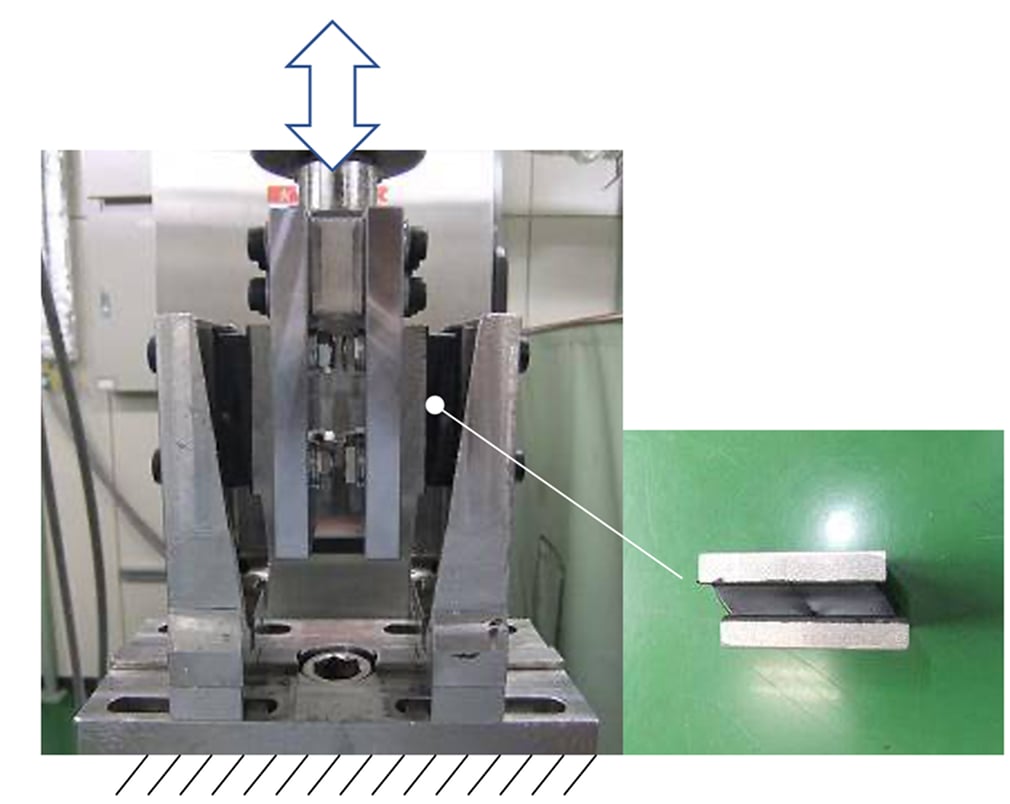

Assuming deformation of the building in the direction perpendicular to the damper installation direction, we also verify the effects during out-of-plane deformation of the damper.

Test overview : Excitation applied by twisting the central flange

Test specimen : Full-scale (□400×t15mm – 2 layers) Frequency f=0.1Hz Shear strain γ=100% Cycles: 4

*Based on the results of tests conducted in July 2014 at Sumitomo Rubber Industries’ Kakogawa Plant.

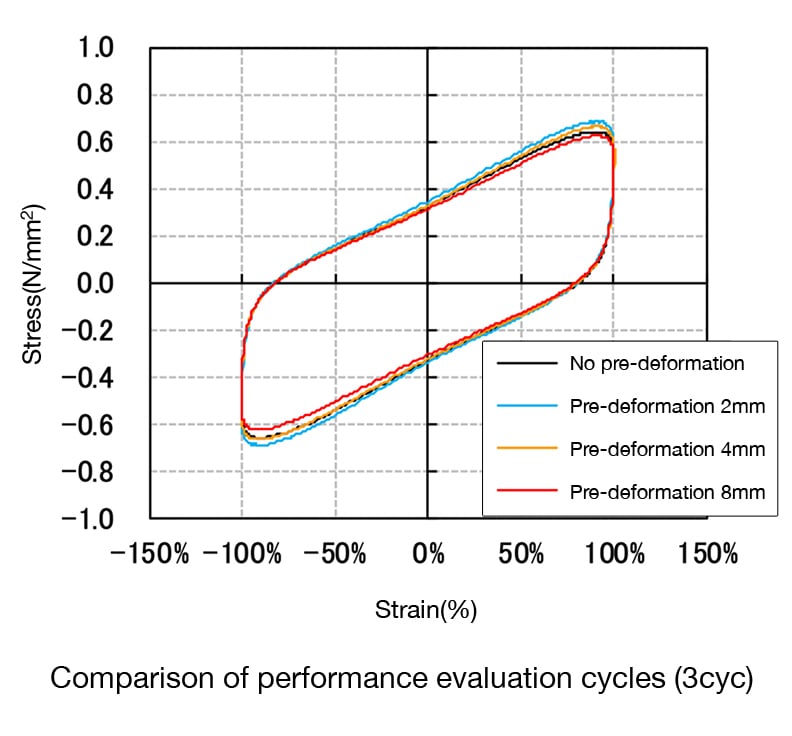

We’ve examined the effects during in-plane perpendicular deformation of the damper, assuming that vertical deformation occurs in the damper.

Test overview:Test conducted by pre-deforming the middle flange in the direction perpendicular to the excitation

Specimen : scaled-down specimen (□40×t8mm) Frequency f=0.1Hz Shear strain γ=100% Cycles: 4

*Based on the results of tests conducted in July 2014 at Sumitomo Rubber Industries’ Kakogawa Plant.

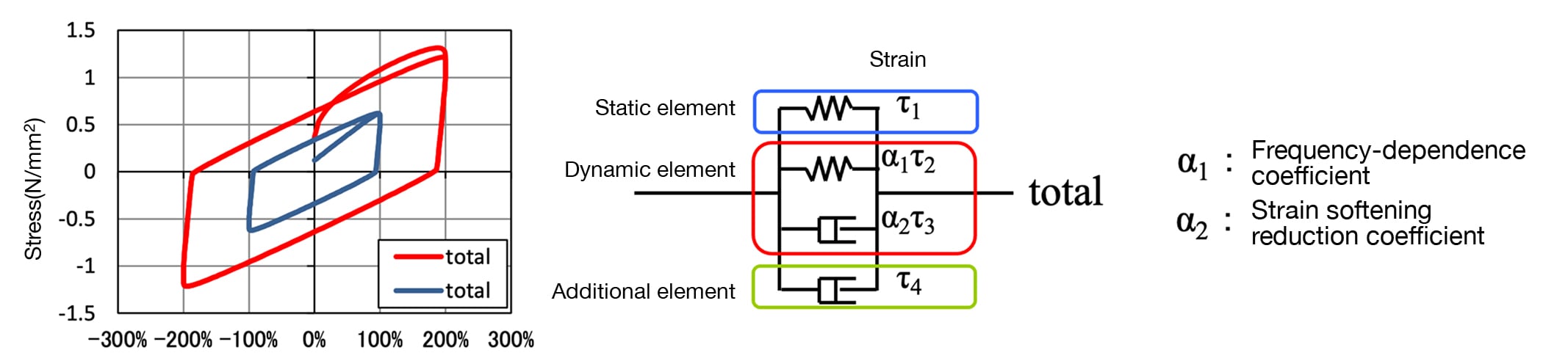

Sumitomo Rubber's vibration control device

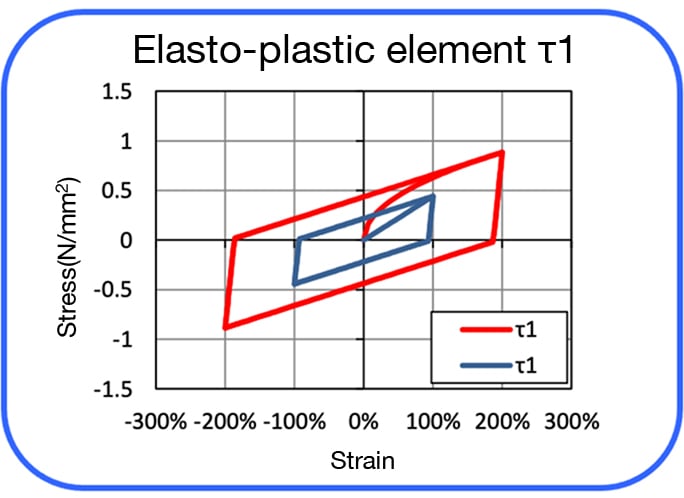

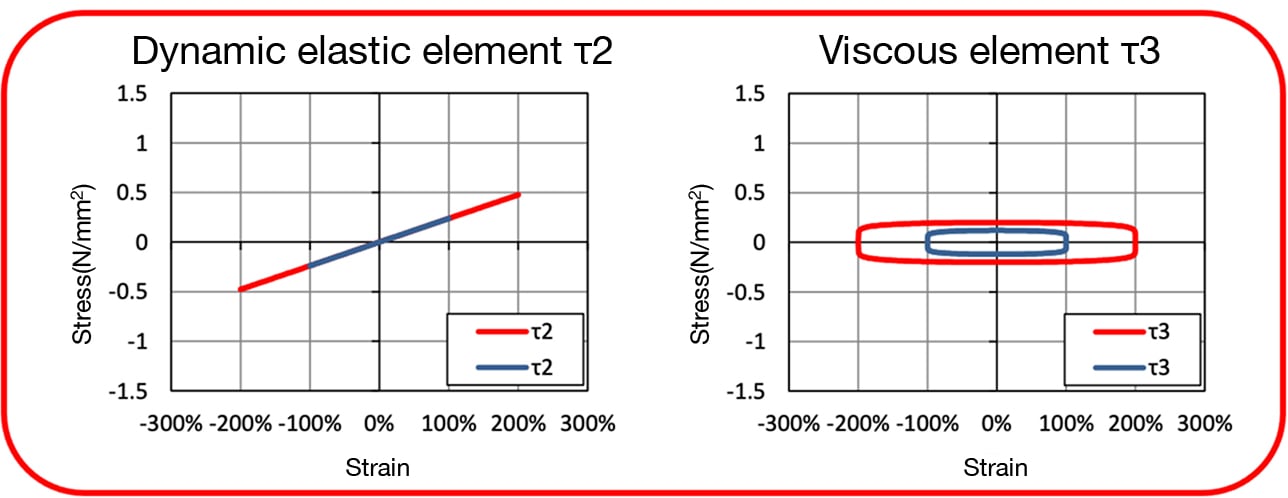

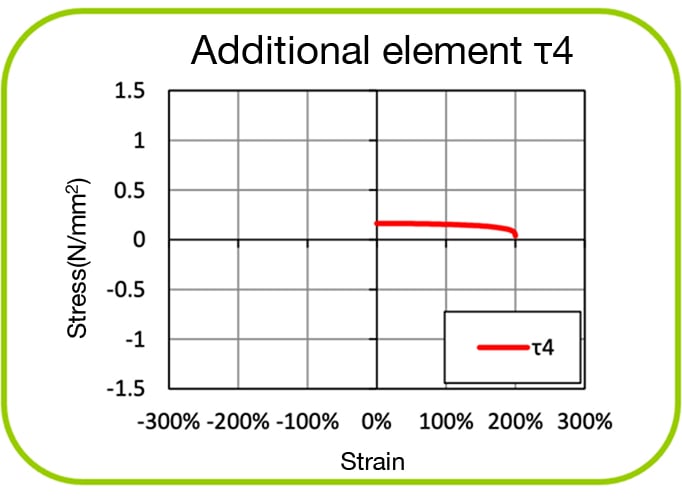

An analysis model has been developed that can accurately represent the properties of high-damping rubber by combining multiple elements.