Shipping inspection method

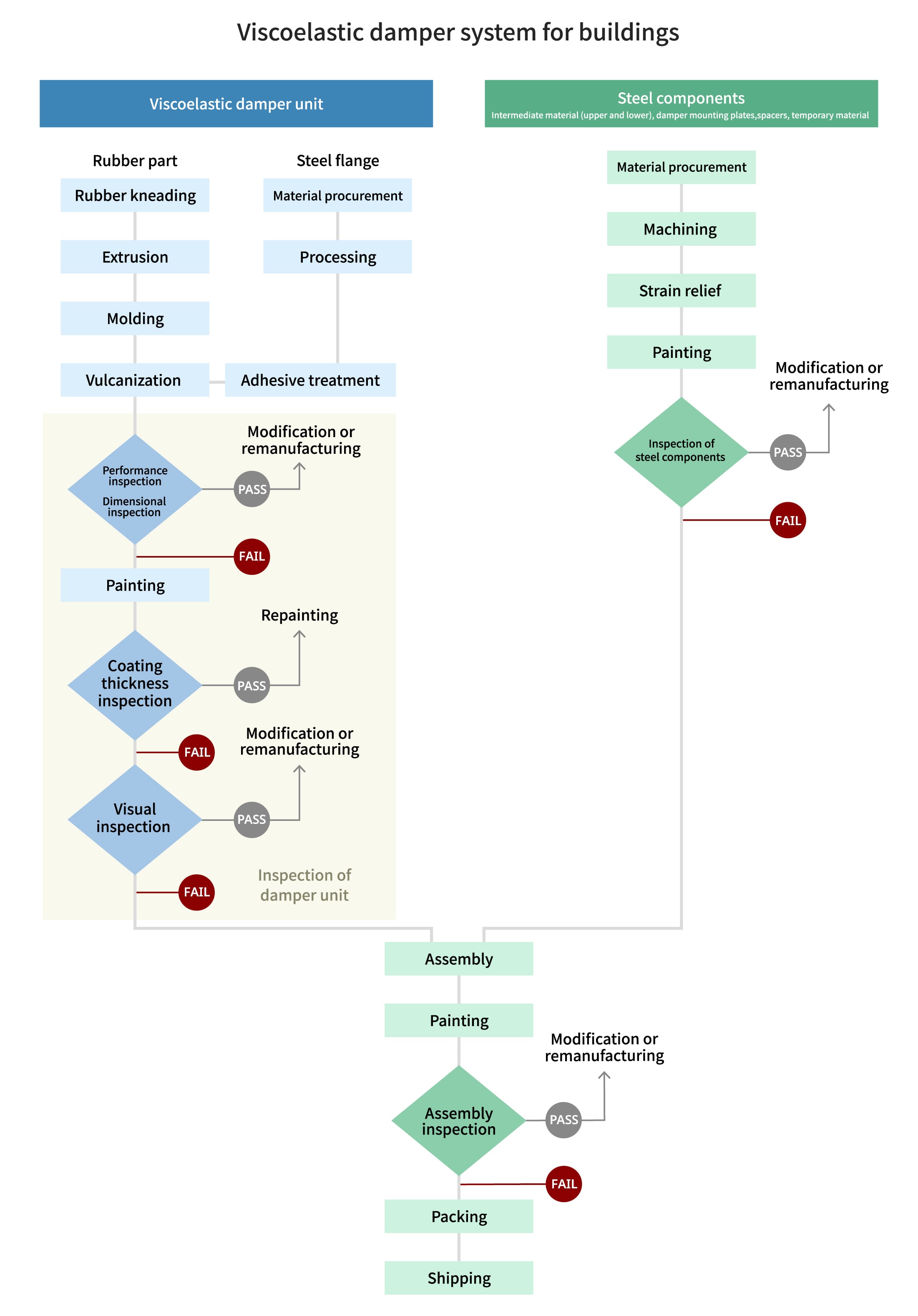

Manufacturing process

At every stage of the manufacturing process, quality control is conducted based on internal standards and external regulations.

Under the following quality management system, Sumitomo Rubber delivers highly reliable products.

Materials used

In the manufacturing of dampers, we use highly reliable materials that comply with various standards.

| Item | Applicable standards and certifications | ||

|---|---|---|---|

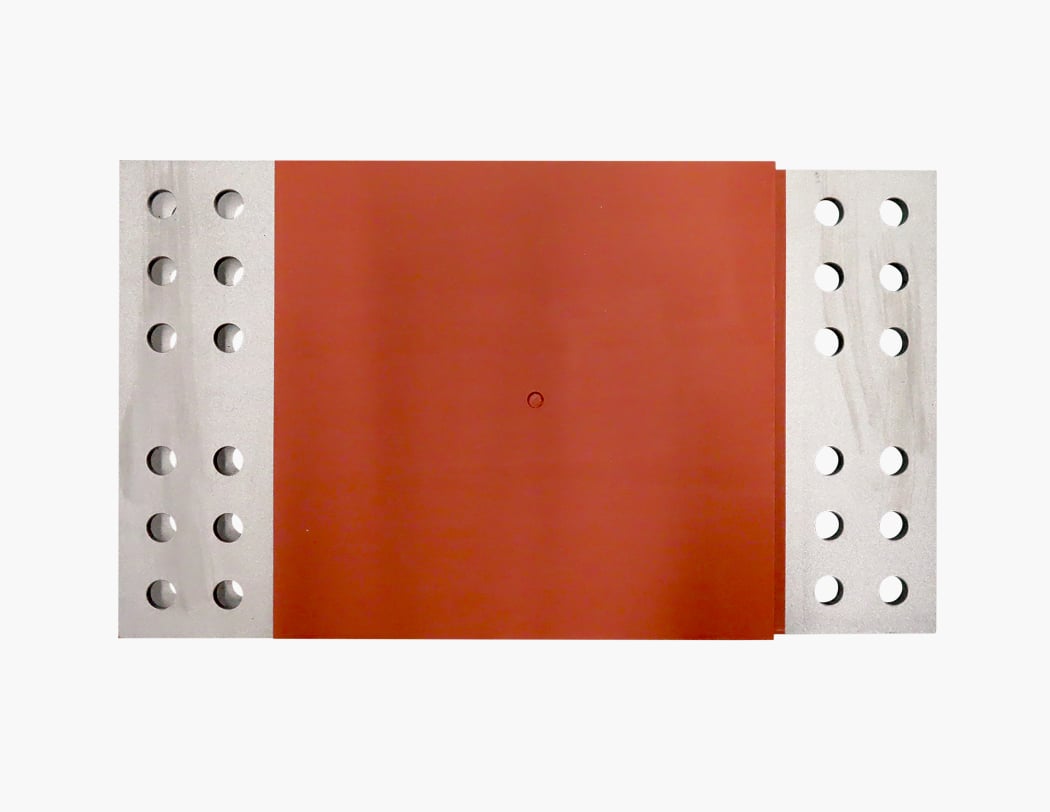

| Viscoelastic damper system | Viscoelastic damper unit | Flange | JIS G 3106 |

| High damping rubber | GBRC Performance Certification No.11-30 | ||

| Damper support frame | JIS G 3106 | ||

| Connection plate | Mounting plate | JIS G 3106 | |

| Spacer | JIS G 3101 JIS G 3131 JIS G 3141 | ||

| Bolt | S10T (Torsion-type) | Certified product from the Minister of MLIT. | |

| F10T (High-strength bolt) | JIS B 1186 | ||

| Temporary material | L-angle | JIS G 3101 | |

| Temporary bolt | JIS B 1180 | ||

| Anti-corrosion coating | JIS K 5674 Type 1 * | ||

*The standard is lead- and chromium-free anti-corrosion paint. Please contact us for other specifications.

Pre-shipment inspection – Performance testing

A steady-state vibration test is conducted on the viscoelastic damper unit to verify the hysteresis characteristic values (Geq, heq) during the performance evaluation cycle.

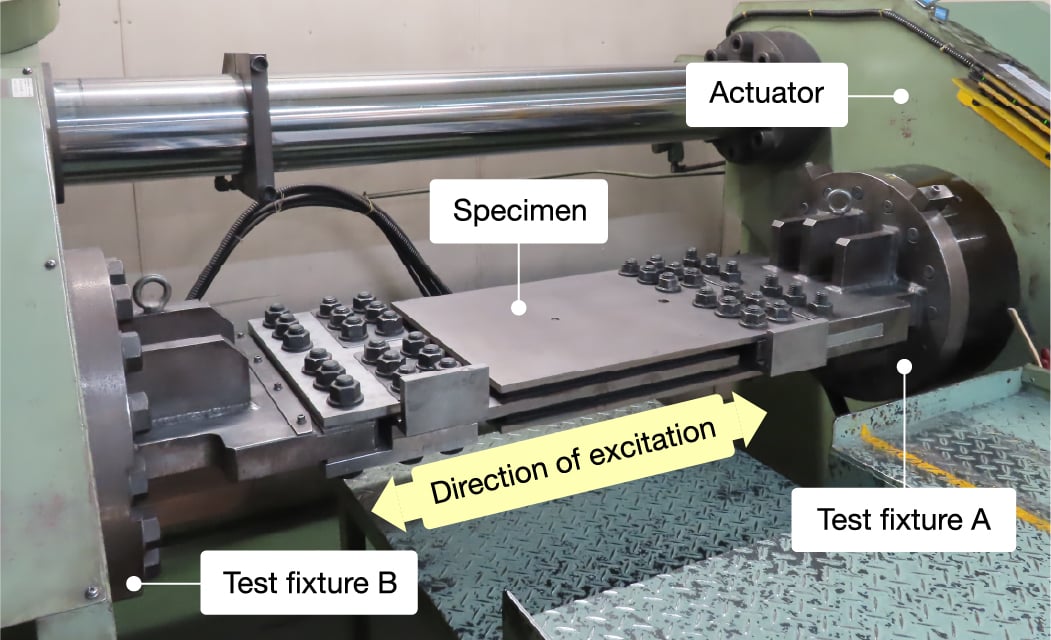

Inspection location and test machine overview

- Test machine name

- 100t Servo Pulsator Testing Machine (Shimadzu Corporation)

- Test Machine Specifications:

- Maximum load: 100 tons

Maximum speed: 15 mm/sec

- Test location

- Sumitomo Rubber Industries, Ltd., Kakogawa factory

Test method

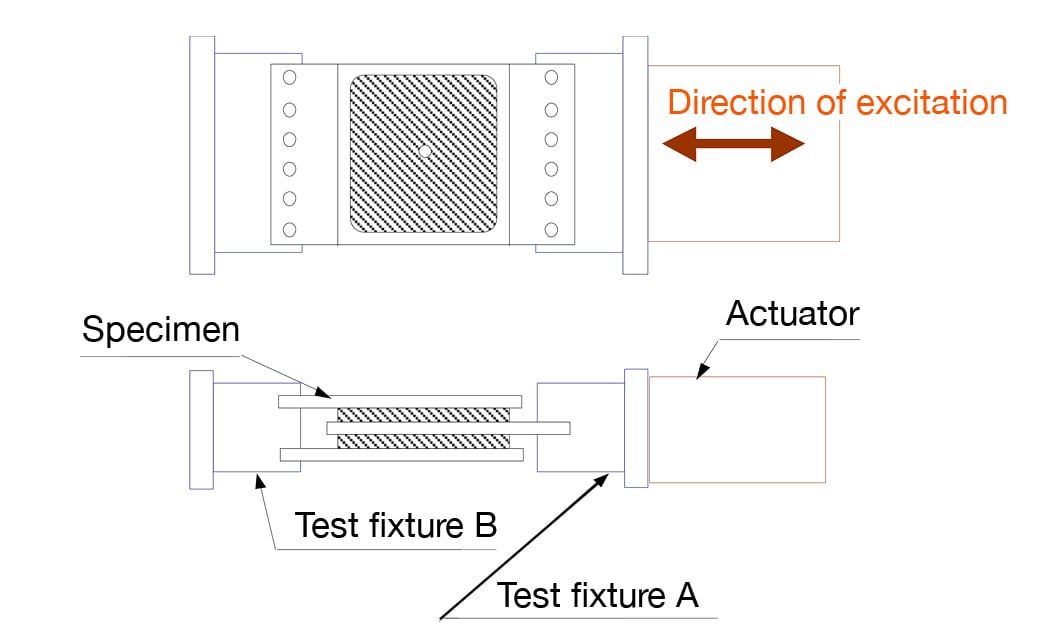

The viscoelastic damper unit is mounted on the testing machine, and a predetermined displacement is applied repeatedly for four cycles. The load-displacement curve is obtained using the displacement gauge and load cell inside the testing machine.

- Excitation conditions

- 4 cycles of sine wave (amplitude: equivalent to 100% shear strain, frequency: 0,05~0.1Hz)

- Test frequency

- All specimens

Vibration test image: 4 cycles of sine wave (amplitude: equivalent to 100% shear strain, frequency: 0.05–0.1 Hz)

Vibration test image: 4 cycles of sine wave (amplitude: equivalent to 100% shear strain, frequency: 0.05–0.1 Hz)Acceptance criteria

Specimens whose equivalent shear modulus (N/mm²) and equivalent viscous damping ratio heq, obtained from the steady-state vibration test of the product, fall within the specified range shall be considered as passing*.

* If the measurement temperature differs from 20℃, a temperature correction shall be applied.

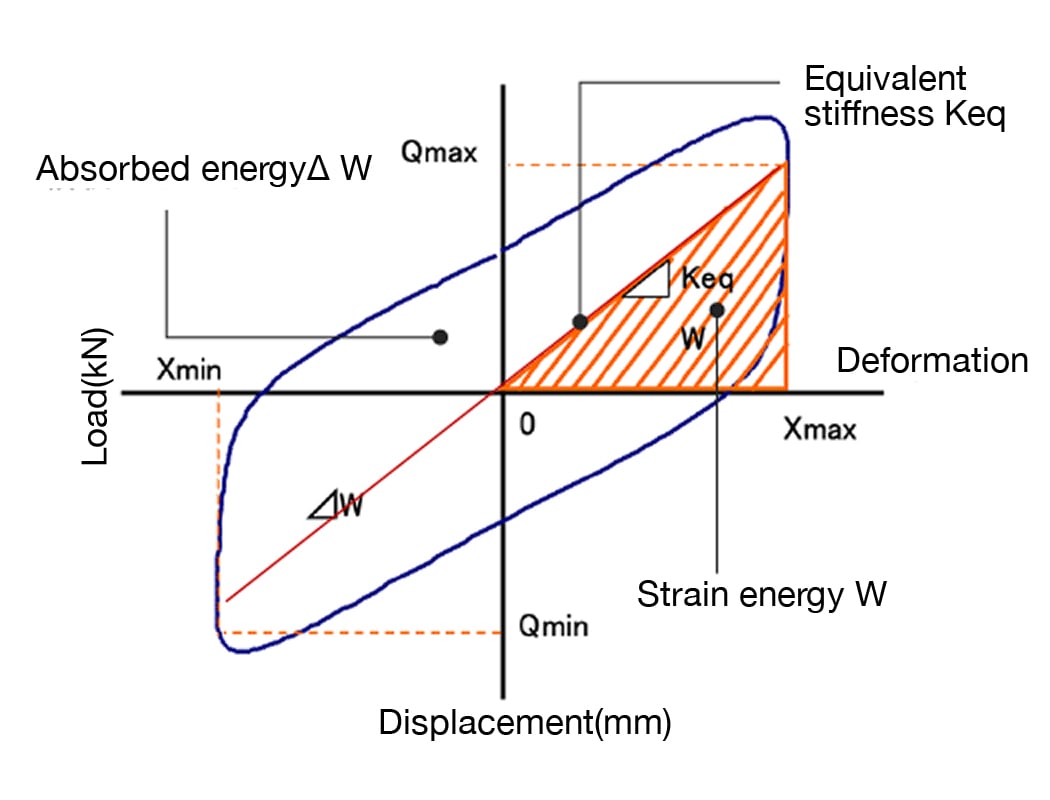

Definition of hysteresis characteristics

Hysteresis loop of a viscoelastic damper

- Characteristic of the damper

- Equivalent stiffness \(Keq\) , Absorbed energy \(ΔW\) , Strain energy \(W\)

- Intrinsic characteristic values of the material

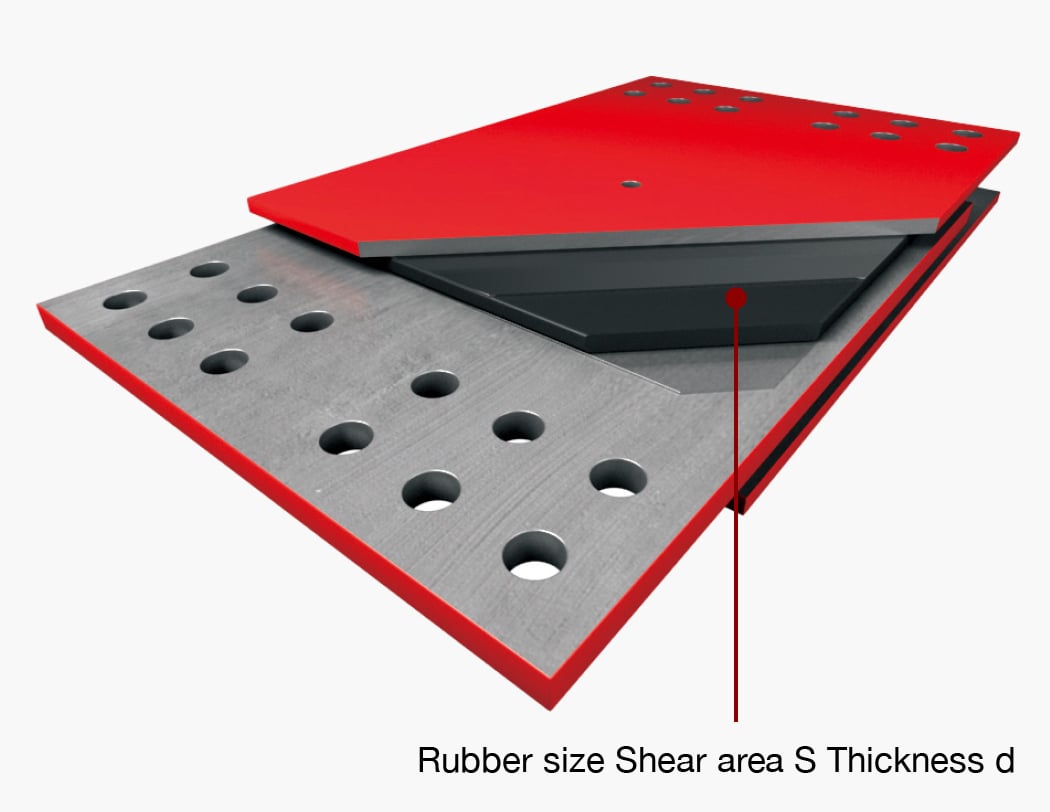

- Shear modulus Geq = Keq×d/S

Equivalent viscous damping ratio heq = ΔW/(4πW)

*heq is an index corresponding to the energy absorption efficiency.

Temperature conversion method

The performance standard values of the damper unit are primarily specified at 20°C. Temperature variations during testing are corrected through temperature compensation. The temperature compensation factor is calculated using an approximate formula based on the rate of change confirmed in advance through tests on scaled-down specimens.

Example of an approximate expression for temperature dependence (Rubber compound GR400)

■ Shear modulus Geq (equivalent stiffness Keq)

\[ \alpha_{1} = 0.0004T^{2} - 0.039T + 1.62 \]■ Equivalent viscous damping ratio heq

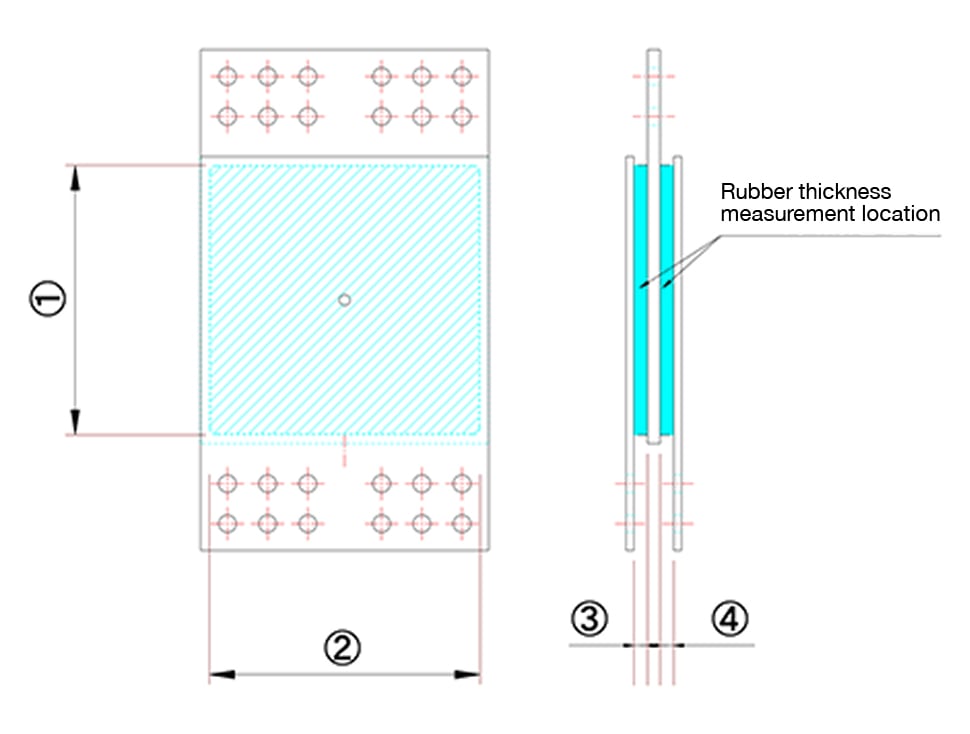

\[ \alpha_{2} = -0.0012T + 1.024 \]Pre-shipment Inspection — Dimensional and visual inspection

Mainly, the dimensions of the rubber parts and the bolt pitch related to the joints are checked.

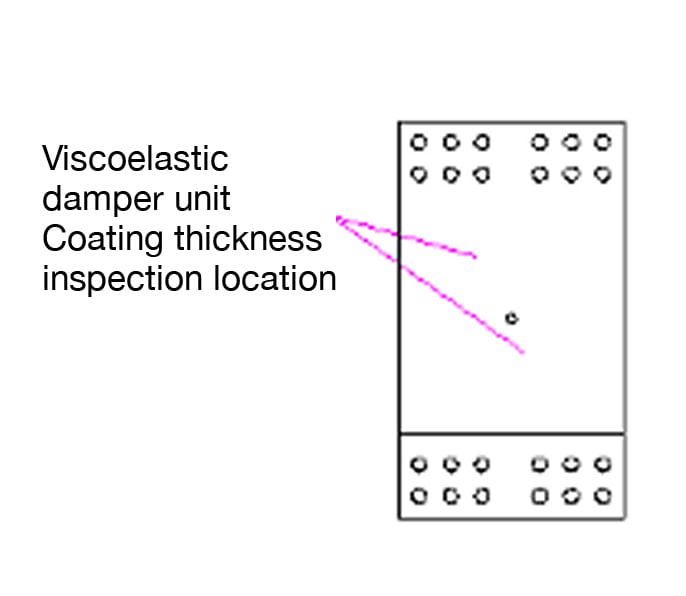

Pre-shipment inspection - Paint film thickness inspection

For anti-corrosion coating, the film thickness is inspected.

| Category | Standard value | Measurement method | Frequency |

|---|---|---|---|

| Viscoelastic damper unit | In accordance with the paint used | We measure the coating thickness using an electromagnetic coating thickness gauge. | 100% of items |

Quality control in performance testing

In response to the National Housing Directive No. 1869 issued on September 30, 2019, we implement the following measures:

Necessary records to verify the reliability and accuracy of performance test results shall be retained for the required period.

- Primary data (raw test data) and secondary data (hysteresis characteristic data before and after temperature correction) from performance tests are automatically saved and stored for the required duration.

Measures to prevent tampering with inspection results shall be implemented.

- As mentioned above, storage of primary and secondary data has been automated.

- Test programs cannot be modified without the approval of the Quality Control Promotion Manager.

- Regular calibration of test machines is conducted, and calibration records are maintained.

The necessary items for the client or a third party designated by the client to confirm that the products meet specified performance requirements shall be defined in the internal standards.

- Standardized documents regulating the test system and data storage rules have been established, and management is conducted accordingly.

- Upon request from the client or a third party designated by the client, stored data are disclosed to confirm product performance.

We have obtained ISO 9001 certification.

Our vibration dampers have been recognized for systematic product quality management and efforts to enhance customer satisfaction, and we obtained ISO 9001 certification, the quality management standard of the International Organization for Standardization (ISO), in April 2025.

Placing quality and trust first, we will continue to provide our customers with high-quality products and services they can rely on, and we sincerely appreciate your continued support.